The Tele-Max company was founded in 1997 and it is located in the heart of Poland (Wloclawek). We offer comprehensive sheet metal processing as well as a metal part assembly services. We want to be an active partner for manufacturing companies that use steel (both carbon and stainless), aluminum or brass/bronze parts in their products. Our equipment allows us to perform cutting, punching, bending, pressing, welding, deburring and machining. Our high production quality is ensured by very modern production technologies and processes, which are supervised by our experienced professionals. Thanks to many years of cooperation with our subcontractors, we are also able to offer galvanized and powder coated products. High quality of products is the foundation on which we build our position. High quality has enabled us to be a supplier to many renowned global companies. We export our products to Spain, Germany, Belgium, Slovenia and Hungary, among others.

The Tele-Max company was founded in 1997 and it is located in the heart of Poland (Wloclawek). We offer comprehensive sheet metal processing as well as a metal part assembly services. We want to be an active partner for manufacturing companies that use steel (both carbon and stainless), aluminum or brass/bronze parts in their products. Our equipment allows us to perform cutting, punching, bending, pressing, welding, deburring and machining. Our high production quality is ensured by very modern production technologies and processes, which are supervised by our experienced professionals. Thanks to many years of cooperation with our subcontractors, we are also able to offer galvanized and powder coated products. High quality of products is the foundation on which we build our position. High quality has enabled us to be a supplier to many renowned global companies. We export our products to Spain, Germany, Belgium, Slovenia and Hungary, among others.

Next to high quality of products our strength is:

In 2019, the part of Tele-Max production was launched in a new production area in the Brzeska Economic Zone in Pikutkowo 37E. Most of the machinery was moved there from the company's basic location in Wlocławek at 28 Krzywa Gora Street.

In 2019, the part of Tele-Max production was launched in a new production area in the Brzeska Economic Zone in Pikutkowo 37E. Most of the machinery was moved there from the company's basic location in Wlocławek at 28 Krzywa Gora Street.

In the same year, the Research and Development Center for Coating Technologies was launched in Pikutkowo. The R&D infrastructure launched there enabled industrial and development work to be carried out in accordance to the long-term Tele-Max strategy.

Currently, the R&D Center significantly enriches the company's offer by fulfilling the following functions for customers:

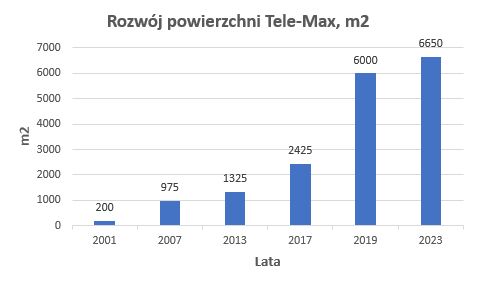

The impressive development of production infrastructure has been illustrated below.